Creating tomorrow’s fuel cell catalysts at industrial scale

Fuel cell catalysts: a continuous quest for quality

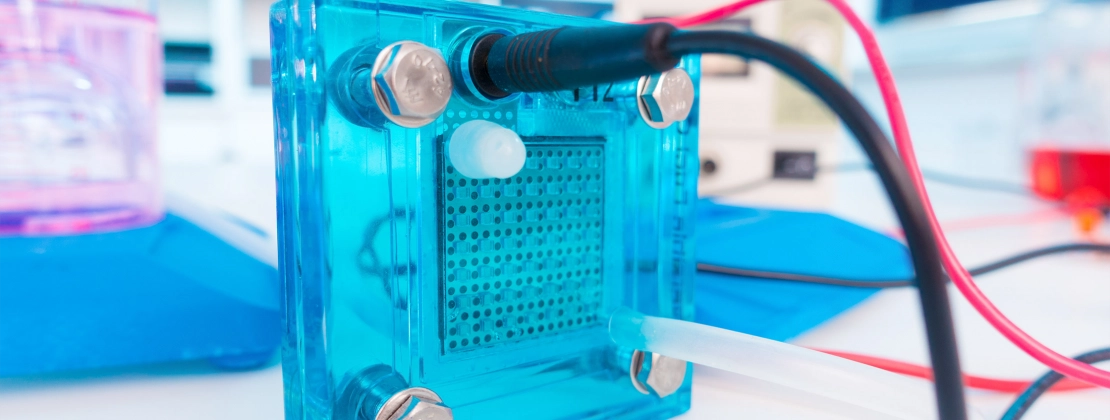

Fuel cells generate electrical energy from hydrogen with the help of catalyst layers on both sides of the membrane: the cathode and the anode side. These catalysts are nano-sized particles (often between 2 to 5 nanometers) based on platinum powder. At Umicore, we work on continuous improvement: how can we make tomorrow’s fuel cells more efficient than today’s with our PEM catalysts? We focus on the evolution of highly efficient, reliable and mature fuel cell technology and closely follow new innovations in the field.

Everything starts with a fundamental understanding, both of the science behind fuel cells and the market needs. Together with our research and industry partners, we then look at how to improve our PEM fuel cell catalysts to meet specific requirements: from withstanding extreme conditions with a reasonable energy input to reducing the amount of precious materials required, thus also cutting down on cost.

Why nanoparticles as catalysts? Because they have a large surface area in relation to the amount of material used. This results in a minimum of required material. The downside, however, is that the quality of conventional catalyst materials can vary greatly. Therefore, R&D at Umicore is mainly focused on overcoming that challenge..

Hitting the right notes

How can we make tomorrow’s fuel cells more (cost-)effective? At Umicore, the answer is fivefold:

| Combining various perspectives – None of us is as smart as all of us together. That is why we tap into all the expertise in our ecosystem. We listen to our customers and suppliers, we stay up to date on the latest research, and we collaborate with universities and knowledge institutes in open innovation projects. Last but not least, we have an industry-leading R&D team in place to complement external insights with decades of experience and acquired knowledge. |

| Setting up the right processes – Creating fuel cell catalysts happens through synthesis. The nature of the specific process is defined by a lot of parameters, such as temperature, pressure and concentration. Needless to say, these parameters have to be 100% exact and must be carefully monitored to ensure complete stability, batch after batch. Our optimized, reproducible processes guarantee maximum control over the nanomaterials’ properties. |

| A customer-centric mindset – With a portfolio of different catalysts and additives for PEM fuel cells, Umicore caters to many customers, including OEMs and membrane electrode assembly manufacturers (MEAs). The goal, however, is always the same: boosting range performance and durability – something we achieve with dedicated technologies, superior quality management and a deep understanding of the automotive industry. |

| In-house control – In our R&D environment – and, of course, production as well – we can control all structural parts of PEM fuel cell catalysts. We also master the complex analytical methods to capture and interpret the data necessary to finetune nanoparticles to achieve both stability and high performance. Step by step, we turn every drivetrain development project into a successful result meeting customer’s expectations. |

| Large-scale production – Many organizations are conducting exciting research into fuel cell catalysts and are able to show amazing results on lab scale showing the potential for further developments. But the automotive industry craves industrial-sized solutions and that is where we come in. We take the steps to scale up the proven technology. We can deliver mass and sustainable catalysts demands, thanks to efficient and ethical sourcing, state-of-the-art equipment and decades of practical experience. |

“Catalysts for PEM fuel cells are nano-sized particles. Developing those at industrial scale – in metric tons – without loss of properties is quite unique in the market.”

Daniel Herein, Senior Manager Global Research & Technology at Umicore

From theory to practice: the AutoStack Industrie (ASI) project

In Germany, Umicore is part of a EUR 60 million government-funded research project called AutoStack Industrie. Launched in 2017, the project brings the entire German fuel cell supply chain together. The goal: to develop a fuel cell stack suitable for mass production in the German automotive industry by bringing key technologies to industrial maturity.

Together with major OEMs (Volkswagen, Audi, BMW, etc.), suppliers (Greenerity, Dana, etc.) and renowned research institute ZSW, Umicore is playing its part in scaling up the industry, both in terms of fuel cell design and manufacturing.